Delhi

Capacitor Manufacturing Machinery

Leading Manufacturers, Exporters, Wholesaler and Importer of Automatic Dispensing Machine for Resin Potting, Automatic Metal Spray Machine for Capacitors, Automatic Testing Machine for LT Power Capacitors, Automatic Winding Machines for Plastic Film Capacitors, Automatic Wire Welding Machine for Capacitors and Hot Pressing Machine for Flat Capacitors from Delhi.

| Business Type | Trader, Importer |

| Power | 6-9kw |

| Packaging Type | Wooden Box |

| Usage | Auto Electronics Industry |

| Type | Automatic Resin Potting Machine |

| Voltage | As per Customer |

| Condition | New |

| Driven Type | Electro-mechanical |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | South Korea |

| Operating Mode | Automatic |

| Payment Terms | T/T |

| Packaging Details | Export worthy Wooden Packing |

Preferred Buyer From

| Location | Worldwide |

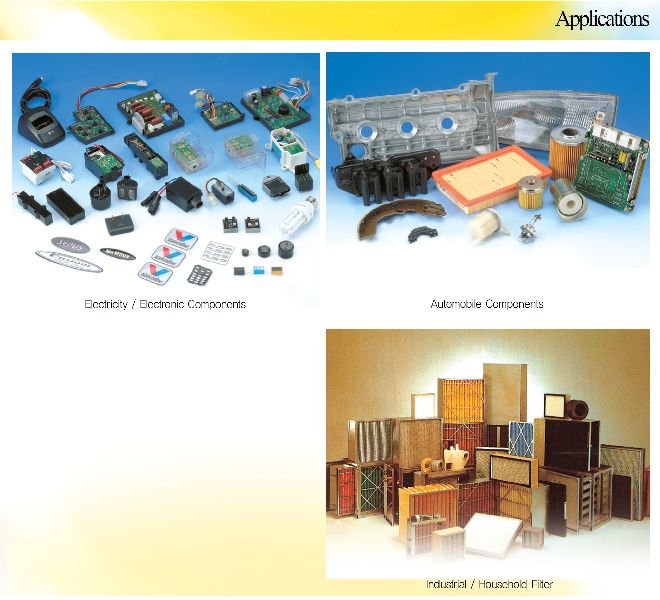

This is an Automatic Meter + Mix + Dispensing System for multi-components like Epoxy, Silicone, Polyurethane, etc.

It is a custom-made production system which is used in Automotive Electronics, filters, electronic/electrical industry.

MOQ : 1 Set

| Business Type | Trader, Importer |

| Type | End Metal Spray on Capacitor Elements |

| Voltage | As Per Customer |

| Condition | New |

| Power | 10 ~ 30kw |

| Packaging Type | Wooden Box |

| Driven Type | Electro-mechanical |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | China |

| Operating Mode | Automatic |

| Usage | Plastic Film Capacitor Industry |

| Port | Chinese Seaport |

| Payment Terms | L/C, T/T |

Preferred Buyer From

| Location | Worldwide |

The machine is designed for electric arc spraying of Zinc metal layers on the top of capacitor elements wound with metallized film. Due to the metal spray, the capacitor plates (within the element) are short-circuited on each side, hence, the capacitor is made non-inductive. Further, the Zinc deposit serves as a base for connecting the leads. Prior to spraying, the capacitor elements must be assembled into a reel of max. 600mm diameter. The capacitor elements are placed on the net support which rotates during metal spray process. The machine has three electric arc guns mounted on the shaft driven by the servo motor system for moving in radial direction of the rotating net. With three guns, it is possible e.g. to spray the first fine layer of zinc, then the second & third rough layer of zinc building the apt thickness of metal spray. The time interval between the different spraying operations is kept minimum to prevent oxidation and assures perfect cohesion of the layers. The spraying plant design assures a uniform thickness of the metal layer. The machine is controlled by PLC and fully automatic. The only manual job requested are loading capacitor elements, reverse side and unloading.

MOQ : 1 Set

| Business Type | Trader, Importer |

| Type | Testing Machine for LT PFC |

| Voltage | As per Customer |

| Condition | New |

| Power | 20 ~ 30kW |

| Driven Type | Electro-mechanical |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | China |

| Port | Chinese Seaport |

| Payment Terms | L/C, T/T |

| Packaging Details | Standard Wooden Box Packing for Exports |

Preferred Buyer From

| Location | Worldwide |

For Testing Electrical Parameters of LT Plastic Film Power Factor Capacitors

MOQ : 1 Set

| Business Type | Trader, Importer |

| Application | Industrial |

| Color | Grey |

| Condition | New |

| Frequency | 50Hz,60Hz |

| Power | 0-5Kw |

| Driven Type | Electric |

| Phase | Single Phase |

| Country of Origin | China |

| Port | Chinese Seaport |

| Payment Terms | L/C, T/T |

| Packaging Details | Packed in Wooden Case suitable for Export |

Preferred Buyer From

| Location | Worldwide |

Automatic Winding Machines used for winding metallized Plastic film on cores to make capacitor elements for AC Capacitors.

Customized machinery. Prices shall vary accordingly.

MOQ : 1 Set

| Business Type | Trader, Importer |

| Type | Lead Wire Welding on Metal Sprayed Capacitor Elements |

| Voltage | As Per Customer |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 5-10kw |

| Driven Type | Electro-pneumatic Mechanical |

| Warranty | 1year |

| Country of Origin | China |

| Payment Terms | L/C, T/T |

| Packaging Details | Standard Wooden Box Packing for Exports |

Preferred Buyer From

| Location | Worldwide |

The machine is designed to attach PVC insulated multi-strand copper lead wire on the Zn sprayed ends of the capacitor elements.

Material specification:

1.Element dimensions: Ø 16~35mm; length 26~45mm; length:Ø ≥ 1.5 (subject to core being flushed with the sprayed ends). Metal spray thickness: Min. 0.4mm at each end

2.PVC multi-strand lead wire O/D: 1.8~3.0mm (Cu: strand Ø0.18x16 ~ 0.18x35mm)

3.PVC multi-strand lead wire length: 50~350mm

4.Length of PVC multi-strand lead wire stripping & twisting for spot welding: Max. 12mm

Machine key units:

1.Welding power supply unit: Inverter type with air-cooling of welding tips

2.Element feeding unit: vibration bowl

3.PLC control. The manufacturer can access machine PLC via Team Viewer for diagnosis.

MOQ : 1 Set

| Business Type | Trader, Importer |

| Type | Flattening of Plastic Film Capacitor Elements |

| Voltage | As Per Customer |

| Condition | New |

| Power | 15 ~ 25kW |

| Driven Type | Servo-hydraulic |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | China |

| Port | Chinese Seaport |

| Payment Terms | L/C, T/T |

| Packaging Details | Standard Wooden Packing for Exports |

Preferred Buyer From

| Location | Worldwide |

Machine designed to apply pressure and heat to wound capacitive elements which are wound with metallized film. Through pressing and heating process, capacitive elements will get stable capacitance value, overall shape and dimensions.

Features:

•Vertical pressing by oil hydraulic system, easy operation, stable process quality.

•Higher output capacity.

•The pressure in oil hydraulic cylinder is controlled by sensing unit, servo dynamic management, higher pressure stability with German digital pressure gauge.

•Temperature module control, uniform temperature, and high precision.

•Pressing in the space of constant temperature, elements are baked more uniformly and energy saving.

•Insulated hot zone for better energy efficiency.

•Auto closing & opening of front doors for improved thermal efficiency.

•Adopting Mitsubishi PLC control, stable and reliable.

•99 recipes can be stored.

•Inbuilt software for calculating time & pressure of the press.